Glycol Injection Package

Glycol Injection

Glycol Injection

We have more than 25 years’ experience in manufacturing and assembly any type of chemical package

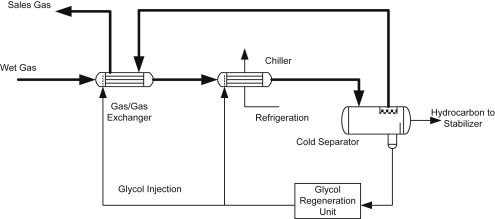

Wet gas can be chilled to meet pipeline water as well as hydrocarbon dew point specification using the glycol injection process, which includes propane refrigeration for chilling. Glycol injection is preferred by most pipeline operators because of its simplicity. The process flow schematic for a glycol injection dehydration system is shown in below Fig.

Glycol injection systems are the lower cost option than TEG dehydration unit or fixed bed dehydration systems. The lowest temperature at which ethylene glycol injection units can be operated is −30°F. Below this temperature, the viscosity of glycol becomes too high for good phase separation. Beyond this temperature, methanol injection or other dehydration techniques should be considered.